-

Parallel Threading Rebar Coupler

Material: 45# high quality carbon steelMore +

Introduction: Parallel Thread Rebar couplers are devices used to join lengths of rebar together, allowing to quickly and safely create a high performance splice on the construction site. Usually, the rebar ends need to be prepared to connect two bars. This is done by specific equipment which GLUS has engineered and manufactured.

-

Upset Forging Rebar Coupler

Material: 45# high quality carbon steelMore +

Introduction: GLUS upsetting forged rebar couplers offer a full strength connection together with enhanced fatigue resistance. They are suitable for projects of any size, including those requiring a high volume of couplers, such as road and rail bridges. Each end of the rebar to be joined is cut square and enlarged using a cold forge process. A thread is then formed on the enlarged bar end using a thread rolling machine. The thread is such that the cross-sectional area of the bar ends are not reduced ensuring the strength of the connection matches or exceeds that of the parent bars.

-

Squeezing Rebar Coupler

Material: 20# high quality carbon steelMore +

Introduction: Put rough metal in the cold extrusion die cavity, and then punch the metal on the press machine to create cold extrusion couplers through plastic-deformation at room temperature.

-

Half Threading Machine

It’s made up of clamping mechanism, feed slide plate, reducer and rolling head, cooling system and electrical system. It’s mainly used for rolling ribbed rebar in construction project.More +

-

Full Threading Machine

It’s made up of clamping mechanism, feed slide plate, reducer and rolling head, cooling system and electrical system. It’s mainly used for rolling ribbed rebar in construction project.More +

-

Upset Forging Machine

Application: The straight thread rebar upsetting machine is used for mechanical splicing of steel reinforcing bars at first stage. After extruding and upsetting with the rebar end, the cross-sectional area gets bigger, it is suitable for Ⅱ and Ⅲ grade building reinforcing bar with diameter from 16mm to 40mm.More +

-

Roller Dies

Material: Alloy SteelMore +

Application: Spare parts of thread rolling machine, rolling out of thread through metal plastic-deformation.

Type: Regular, High Strength, Super High Strength

Size:

A25: thread pitch 2.5, suitable for rebar φ14mm- φ22mm;

A30: thread pitch 3, suitable for rebar φ25mm-φ32mm;

SA30: thread pitch 3, suitable for rebar φ36mm-φ40mm;

-

Peeling Blade

Material: Alloy SteelMore +

Application: Spare parts of thread rolling machine, used for rebar rib-stripping

Size (mm):

25*25*8,

25*25*10,

25*30*10

One set includes four pieces

-

Eccentric Shaft

Material: Alloy steelMore +

Application: Used to adjust center distance between axes

Diameter (mm): 30mm

-

Testing Bar

Material: Iron/ AlloyMore +

Application: Test the blade accuracy of thread rolling machine

Size (mm): 16, 18, 20, 22, 25, 28, 32, 36, 40

-

Rebar Coupler Covers

Material: PlasticMore +

Application: It is used to cover rebar coupler, ensure that no concrete debris will enter the coupler, and protects the coupler thread not be damaged by sand or others.

Size (mm): 16, 18, 20, 22, 25, 28, 32, 36, 40

-

Rebar Caps

Material: PlasticMore +

Application: It is used to protect rebar thread, so as to prevent bumping and rusting.

Size (mm): 14, 16, 18, 20, 22, 25, 28, 32, 36, 40

-

Plastic A Spacers

Material: PlasticMore +

Application: This Spacer is used for rebar protective layer, which is specially designed to ensure that rebar is not corroded and meets the structural safety.

Size (mm): 15, 20, 25, 30, 35, 40, 50

-

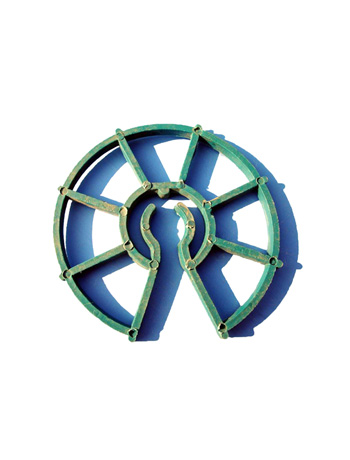

Plastic Circles

Material: PlasticMore +

Application: Use to space rebar, and control the thickness of concrete protective layer.

Size (mm): 15, 20, 25, 30, 35, 40, 50

-

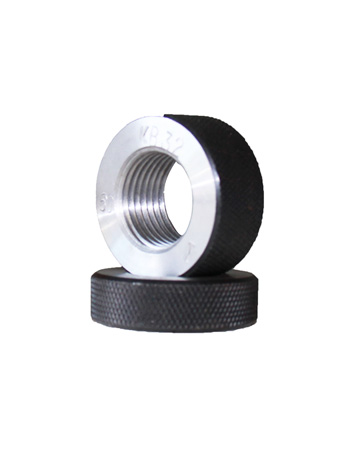

Ring Gauge

Introduction: One set has two, one is a GO side, the other is NOT-GO sideMore +

Material: Iron/ Alloy

Application: Ring gauge is a kind of measuring tool, which is used to detect rebar thread

-

Plug Gauge

Material: Iron/ AlloyMore +

Application: Used to detect the thread of coupler

Pitch Angle: 60°, 75°

Size (mm): 16, 18, 20, 22, 25, 28, 32

-

Work Wrench

Material: Iron/ AlloyMore +

Application: It works on the rebar to get firmly combination with couplers

Size (cm): 65/ 40

-

Torque Wrench

Material: Iron/ AlloyMore +

Application: The torque can be set according to the size of rebar, so as to avoid improper strength by hand handling.

Size (cm): 75

-

Welding Rebar Coupler

Material: 45# high quality carbon steelMore +

Introduction: GLUS weldable rebar couplers provide a convenient means of connecting reinforcing bars to structural steel plates or sections. Shorter than the standard coupler, it has a parallel thread at one end. The other end is welded directly to the steel. The load conditions at the connection must be determined by the designer along with the type and size of weld required. It adopts high performance low carbon alloy steel (20Cr) as material to ensure the welding quality. Another important consideration is the type of electrode to be used, which must be matched to the properties of the plate and tube, and to the site conditions under which the welding will be undertaken. Welders should be qualified for the type of weld required.

-

Grouting Rebar Coupler

Material: 45# high quality carbon steelMore +

Introduction: Grout sleeve coupler is one of new types in coupler industry, with special customized material, full grouting connection method. GLUS adopts advanced production process with high precision to ensure product quality, produced in large quantities and strictly according to the standards.

admin@gulishi.com

admin@gulishi.com  0086-13530964111

0086-13530964111

GLUS, Liaokeng Road 52-1, Shiyan Street, Baoan District, Shenzhen, China

GLUS, Liaokeng Road 52-1, Shiyan Street, Baoan District, Shenzhen, China

0086-13530964111

0086-13530964111

admin@gulishi.com

admin@gulishi.com